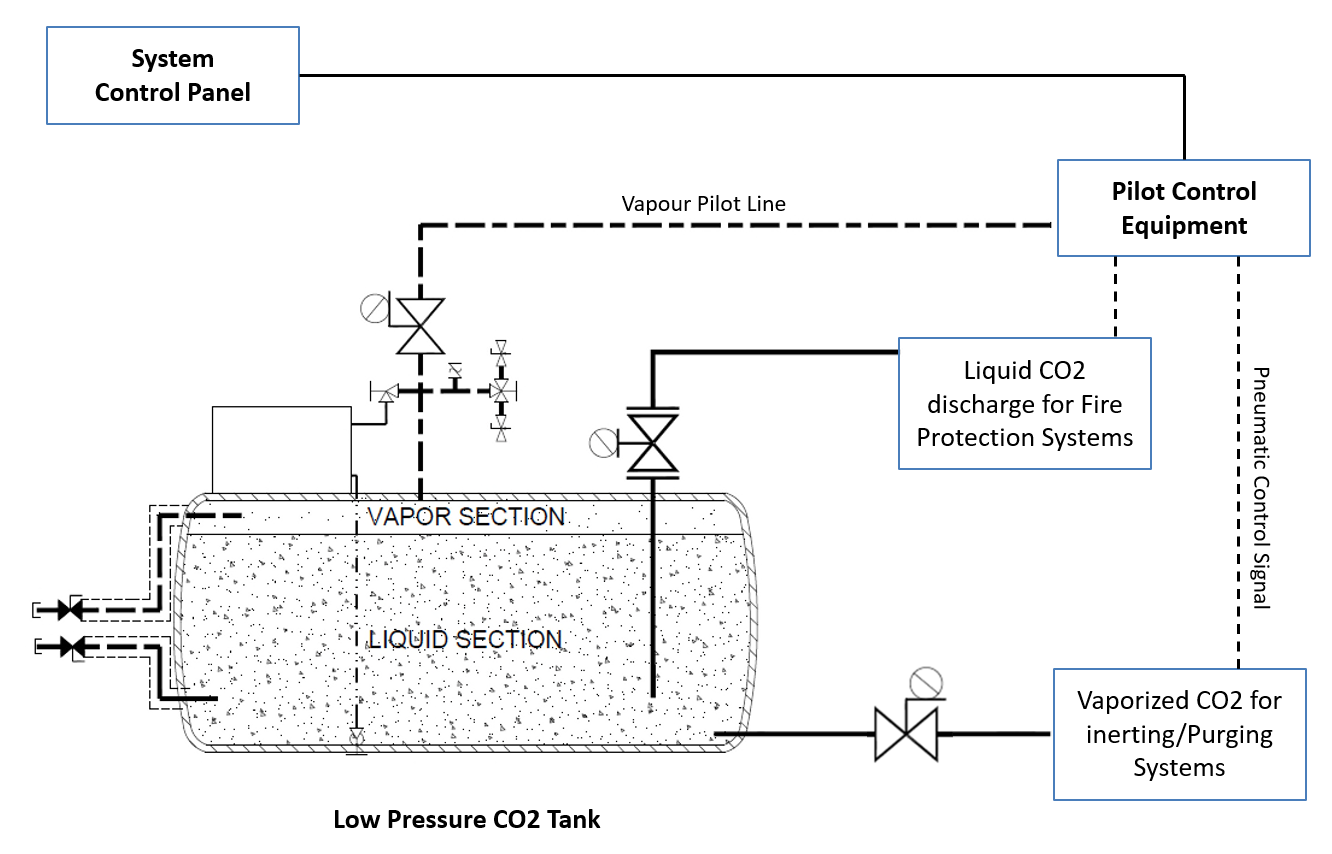

The Kidde Cardox Low-Pressure Carbon Dioxide (LP CO2) System is a proven solution when used to protect areas that require multiple suppression cycles, expansion capabilities, numerous hazards or more than 5000 lbs of CO2.

Total flooding delivers CO2 into an enclosure until the fire is extinguished. For open hazards, the CO2 local application method blankets the hazard extinguishing the flames and cooling the hazard. In “total flooding”, the enclosure of the hazard protected is flooded to a proper concentration. In “local application”, CO2 is directly applied in the proper amount at the rate required to cover the protected hazard.