Clean Agent Fire Suppression System FM200 and Novec1230

FM200™ and Novec™1230

Clean Agent Fire Suppression System

Clean Agent Fire Suppression Systems including FM200, Novec1230 suppress fires quickly

without harming equipment, the facility, inhabitants, or the environment.

without harming equipment, the facility, inhabitants, or the environment.

FM200™ Clean Agent

- Heptafluoropropane (C3HF7)

- HFC-227ea

- Mode of Fire Protection

- Primary:Flame Cooling

- Minor: Chemical Inhinition

- Vapor Pressure: 44 psig

- Suppresses class A, B, and C Fires

- HFC227ea is a responsible choice by any measure:

- Zero Ozone Depletion Potential

- Low Atmospheric Lifetime

- GWP = 3,500

- NFPA 2001, 2012 Edition allows use of HFC-227ea as noted in section 1.5.1.2.1 (c)

- NOAEL = 9% v/v

- LOAEL = 10.5% v/v

- 98% of applications are designed below the NOAEL levels

- Some Class B material may require design concentrations above NOAEL and LOAEL . Refer to the DIOM in these instances

- HFC227ea is: Safe, Can be used in occupied or non-occupied areas, Tested by the US FDA

- Advantages: Cylinder storage space, Rapid discharge time (10 seconds), Rapid suppression (within 30 seconds from discharge), People safety, Equipment safety, Field recharge (available through most OEM distributors), Flexible design using Advanced Delivery Systems, Worldwide acceptance, No agent related downtime

- Applications: Telecommunications, Data Centers, Rare Book Rooms, Clean Rooms, Process Facilities, Control Rooms, Museums/Art Collections

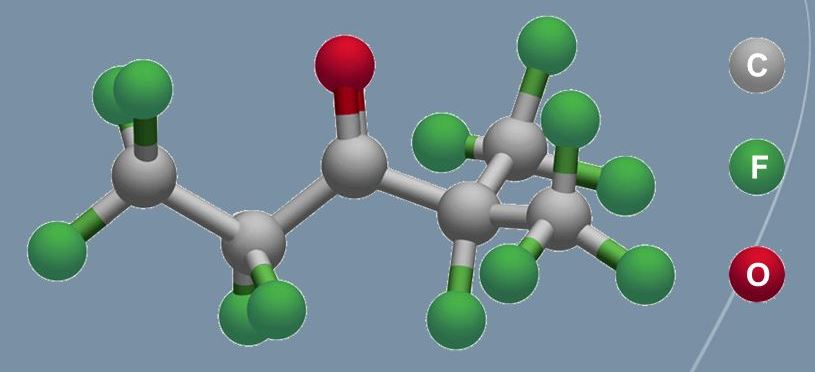

Novec™1230 Clean Agent

- Fluoroketone Introduced in 2003 by 3M

- CF3CF2C(O)CF(CF3)2

- Mode of Fire Protection

- Primary: Flame Cooling

- Minor: Chemical Inhinition

- Vapor Pressure: 6 psig

- Suppresses class A, B, and C Fires

- Novec1230 and the Environment

- EPA SNAP/NFPA 2001 standard

- Safe for people

- Design concentrations well below safety thresholds

- Clean environmental profile: GWP = 1; ATM Life = 5 days

- Liquid at room temperature → low Pv

- No residue

- Electrically non-conductive

- NFPA 2001, 2012 Edition Allows Use of NOVEC 1230 As Follows:

- In Normally Occupied Spaces: Concentrations up to ≥10.0% v/v. Maximum exposure time is no more than 5min

- In Normally Non-Occupied Spaces: Concentrations exceeding ≥10.0% v/v provided occupants can evacuate within 30 seconds. Requested: Lock-out valve, Mechanical time delay, Pressure operated siren and, Signage.

- NOAEL = 10% v/v

- LOAEL > 10.5% v/v

- Most applications are designed below the NOAEL levels.

- The highest concentration percentage for Class B fires published in the DIOM is Methanol at 8.44% v/v.

- Significant safety factor between design concentrations and NOAEL/LOAEL

- Advantages:

- Completely safe and approved for use in occupied spaces

- Best environmental profile of all “active” agent Halon alternatives

- Provides minimum business interruption with maximum asset protection, without agent related downtime

- Environmental “Blue Sky” warranty

- Bulk transport: Low vapor pressure (6 Psig) – air travel

- Offered in: 11 lb Demo Container, 661 lb Drums, 2425 lb totes

- Applications: Pharmaceutical / Healthcare, Data processing centres, Telecommunications (Cell sites, switching centres), Industrial Oil and gas, Museum & cultural heritage, Any environmentally sensitive market or end

DESIGN CLEAN AGENT FIRE SUPPRESSION SYSTEM

- General Requirement:

- Hazard dimensions, access floor, ceiling space

- Fire rated material (Class A, B, C)

- Air leaks effectively sealed and reduced

- HVAC shutdown required

- Normally occupied or Normally unoccupied

- Agent container location and total distance from the hazard

- Main/reserve or main only systems

- Standards (NFPA, TCVN, Environment)

- FM200 NFPA 2001 Concentration 7%, TCVN 7,5 - 7,9%

- Novec1230 NFPA 2001 and TCVN 4,5 – 5,2%

- Environment: NOAEL, LOAEL, PBPK, ODP, GWP, ALT

- Kidde – Flow Calculation Software

- Flow calculation

- Select ECS and ADS

- Piping arrangement

- Selector Valve and

- Budgetary