PROTECTION

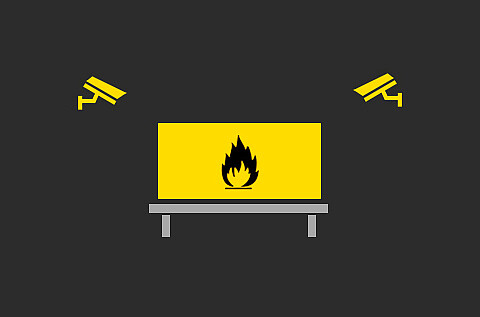

Areas of critical importance, e.g. with dangerous goods tanks, are monitored.

Software analyzes video images for motion in areas where no motion is intended.

The software analyzes the video images for movements in areas where no movement is expected.

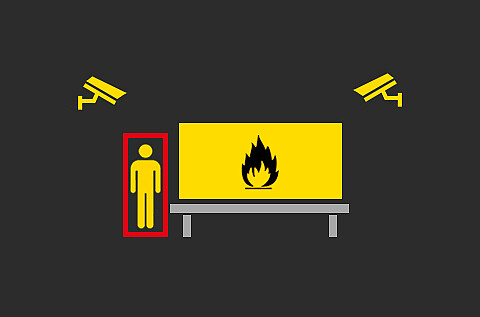

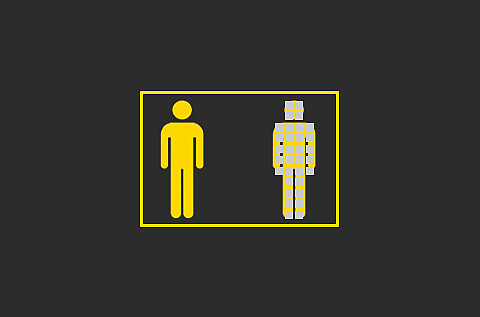

Prdefined screen sections are obscured (pixelated, masked)

Motion is pixelated

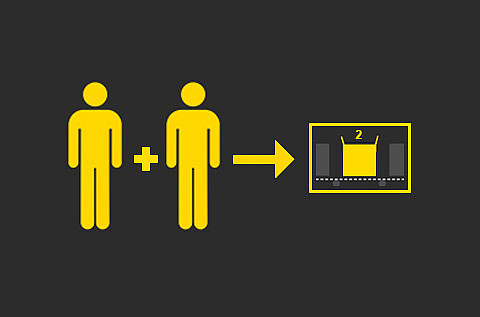

Viewing of the images only under 4-eyes principle

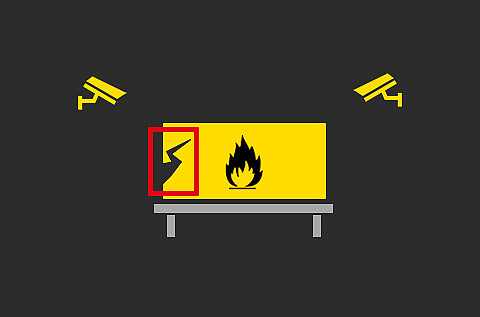

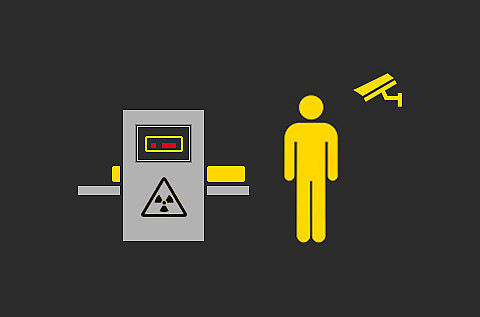

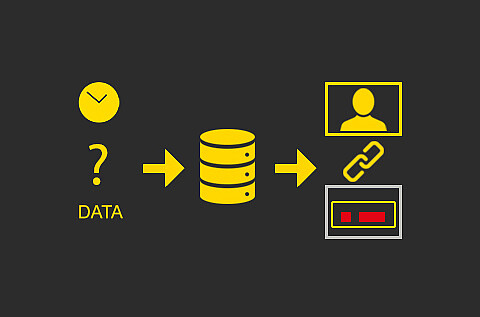

Linking X-ray scanner and video management software

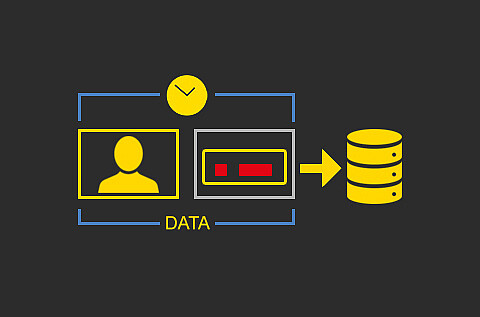

The images are visualized and saved in combination with a time tag and data from the sureillance camera. As a result, all image files are archived in combined form.

If the camera detects suspicious actions, the images can be browsed using various metadata, e.g. time, and then displayed.

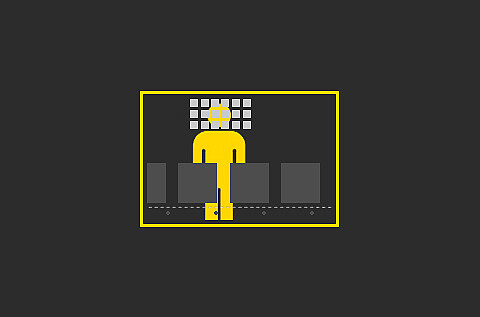

Goods for shipment are missing.

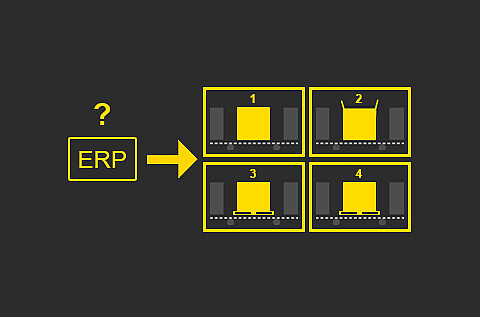

Starting point of the research: Scanning at the point of outgoing goods.

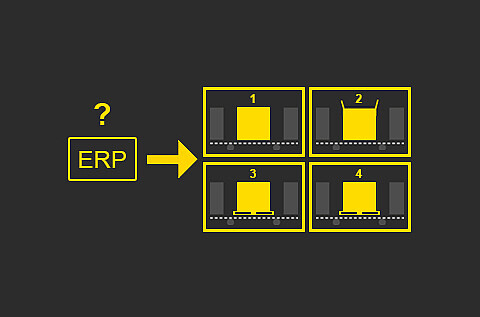

Interfaces between images and ERP systems provide the images required.

Delivery route can be tracked “in house”.

Visual documentation indicates whether the goods were loaded incorrectly.

Also theft can be documented this way.

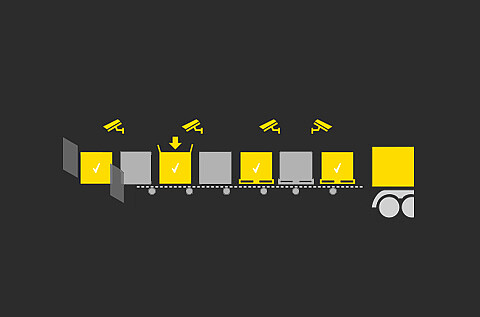

The parcel and packaging process is visually documented

Image data is linked with ERP data

Customer claims damaged goods or argue that goods were not included in the delivery

The images are searched on the basis of the transaction number

Images recorded during packaging process show the quantity and condition of the delivery.